The Most Fashionable Fiber Cement Board You Can’t Miss

For those who like industrial style, a wall panel that cannot be missed in recent years is fiber cement board. George fiber cement board is based on high-quality and high-grade cement, with fiber reinforcement and auxiliary material modification. It is processed by molding, pressurizing, steam curing and other technologies. George panel, an experienced WPC wall panel manufacturer, has the professional technology to produce all kinds of wall panels, this time we will share with you the related science knowledge of fiber cement board.

I. The features of fiber cement board

Fiber cement board is a new type of green and environmentally friendly board. Fiber cement board uses cement as raw material, adds an appropriate amount of adhesive, and then mixes certain fiber materials to make the performance of the cement board more stable, and then processed through several processes. The man-made board has excellent properties such as fireproof, moisture-proof, insect-proof, easy processing, heat preservation, low deformation coefficient, and durability.

Fiber cement board has been waterproofed, so its hygroscopicity is smaller than that of wood, and its shape stability and antibacterial properties are better. Fiber cement board has a uniform structure, smooth and delicate board surface, easy to carry out various finishing treatments, good dimensional stability, uniform core layer, and various thickness and size specifications, which can meet various needs.

II. The appearance of fiber cement board

1. The colors and texture of fiber cement board

Fiber cement board only has a single color, which is natural cement color. The surface of fiber cement board has a unique flax plant texture, slightly rough texture, rough but delicate, vivid and subtle, without carving, showing the beauty of nature. Whether it is viewed from a distance or a close-up view, it is intriguing.

Fiber cement board has the common characteristics of one color throughout the body. It is naturally colored through the crystallization of natural mineral pigments. The beauty of fiber cement board is not only on the surface, but more on the inside. This real texture from the inside to the outside is full of artistic expression, which can give the building facade a rich and vivid expression.

Fiber cement board integrates artistic beauty and functional beauty, and is a trusted creative partner for architects. Many architects who have won the Pritzker Architecture Prize in the world have used fiber cement boards in their works, such as: Ieoh Ming Pei, Norman Foster, Herzog & de Meuron, Ricardo Bofill, Herman Herzberg, Tadao Ando, Kengo Kuma, Yan Xunqi, Wang Shu, Ma Yansong and other international architects.

Spanish architect Antoni Gotti once said, “Nature is beauty, and beauty lies in practicality. Therefore, practicality is the meaning of nature, and nature is the embodiment of practicality.” Fiber cement boards pursue the beauty of nature and practicality, and serve the world Created a lot of high-quality extraordinary buildings.

2. The parameters of fiber cement board

The length and width of the fiber cement board are all 2440*1220. As a professional WPC wall panel manufacturer, George Panel produces fiber cement boards in a variety of thicknesses, from 6mm to 30mm, to meet the requirements of various projects.

III. The advantages of fiber cement board

1. Unique decorative style

The unique texture of fiber cement board is natural and rough. When this element is used indoors, it is full of retro and modern style. It does not require too many colors to be added, and it is naturally more colorful. The color elements of black, white and gray use fiber cement board in a large area to create a calm and rational texture, and create an industrial style and retro style design, which can make you quiet and enjoy the beauty of the space.

The exterior wall design of fiber cement board retains the natural style of the main building. The use of fiber cement board has a rough texture without carving. It seems to be random, but it is eclectic. It miraculously presents a wild and unrestrained space in the space.

2. Unmatched creativity and product applicability

Few other building materials combine the decorative and technical properties of a product as well as fiber cement board. One of the main advantages of fiber cement board is its resistance to various climatic conditions. Freeze-thaw, heat and rain can’t damage it. In construction, fiber cement boards can be used as backing in wet areas, or as fire-resistant panels in dry areas as well as high-strength wall panels.

Architects love the variety of decorative effects that fiber cement boards can express. Fiber cement boards are easy to install and can be cut to any desired size or shape. If you want your home to be in a cool industrial style, fiber cement board is a good choice for you.

3. Environmental protection and saving, high economic benefits

With the development of industrialization in the world, the demand for land is becoming more and more tense, and there are more and more high-rise reinforced fiber cement board buildings. It is usually seen that the decorative materials of the exterior walls of the buildings are mostly veneer tiles, paints, or aluminum plates and stone.

The disadvantages of paints are that they are not durable, they are prone to discoloration, and the appearance quality is usually not guaranteed. The disadvantage of veneer tiles is that the color is inconsistent and they tend to fall off. The craftsmanship of marble, granite and other stone finishes and aluminum plates is relatively complicated and expensive.

In contrast, the craft wall of fiber cement board has good integrity and no hollowing and cracking, which makes the wall more conducive to moisture-proof and leakage-proof, eliminating the need for traditional plastering and other wet operations, reducing the process and shortening the construction period. Save machinery costs, labor costs and management costs, and reduce maintenance costs in the later period.

Compared with stone, fiber cement board reduces the thickness of the outer wall, increases the use space, makes the building utilization rate higher, and greatly reduces the construction cost, so it has good economic benefits. So, if you choose to use cost-effective fiber cement boards, you can get better results for less money.

IV. Practical application scenarios

Fiber cement boards can be used in residential, industrial or agricultural buildings, and are widely used in partition walls, exterior walls and floors of offices, hospitals, factories, villas, theaters and various art buildings. Its appearance and performance advantages are especially suitable for the following application areas:

1. Fiber cement board as exterior wall panel

Beauty is one of the three major elements of architecture. Fiber cement board can be used as a unique architectural finish. It reflects its special artistic style with exquisite and real texture. The gray, hard and cold fiber cement board makes its effect is the same as that of stone. Fiber cement board has stable performance in the open air and high temperature environment, and will not sag or deform.

2. Fiber cement board as partition

Fiber cement boards have excellent dimensional stability, thermal insulation, and sound insulation properties. Fiber cement board has high strength and is not easy to be deformed; light weight, suitable for applications such as roofing and floor slabs; low thermal conductivity, good thermal insulation performance, high product density, and good sound insulation; allowing moisture to diffuse in both directions, moisture can be absorbed, and easy to release. This improves comfort in the building; it has a long lifespan and is resistant to acid and alkali, corrosion, moisture and insect damage.

3. Fiber cement board as floor

Compared with wood floor, fiber cement board as a sandwich floor has the advantages of fireproof, moisture-proof, waterproof, insect-proof, high flexural strength and good sound insulation; compared with concrete floor, fiber cement board is light in weight, which can reduce the load of the building. The strength, coupled with its thin thickness, can increase the space of the floor, fiber cement board is easy to reprocess and cut, and it can be cut into various specifications according to needs.

4. Fiber cement board as industrial style home design background wall

Today’s very popular industrial style design, many people who like this style will bring this style into their homes, and the material that best reflects the cold industrial style is fiber cement board, which can be applied to TV background walls, bedrooms In places such as background walls, the industrial style created by fiber cement boards is very advanced and attractive.

V. Installation guideline

Our fiber cement boards are easy to install. It can be installed on the construction wall directly or on the stainless steel keel. Comparing with the traditional brick wall installation, it can save 50% labor cost and time cost.

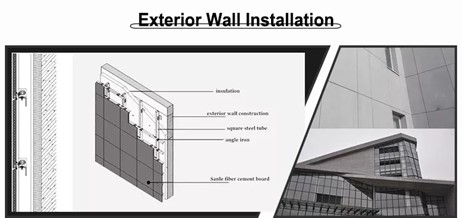

1. Exterior wall installation

(1) Fiber cement board preparation: according to the size and design requirements, installing the supporting aluminum accessories on the back of fiber cement board. Making cross line according to the vertical distance between the transverse keels and length of fiber cement board uniform size, then fixing supporting aluminum fasteners at the intersection, using 10 mm long and 4 mm thick stainless steel screws.

(2) Construction wall preparation: cleaning up the wall surface, and then marking out the position lines and partition lines of the steels according to the design drawings and actual needs.

(3) Wire hanging: vertical wire hanging should use the steel wire, with 8-10 kgs weight lower counterweight iron, and the upper end is hung on the special wire hanging angle iron frame. The angle iron frames are fixed on the top corners of the wall with expansion bolts, and marking on the top and bottom of the control line.

(4) Keel installation: first, fixing angle iron on the structural surface with expansion bolt. After that, installing the fastening angle iron and the transverse aluminum keel. The connection between angle iron, square steel tube and transverse keel is made with bolts. Last, using the infrared level meter to detect whether the horizontal aluminum keel is horizontal, and the steel line to detect whether it is vertical.

(5) Fiber cement board installation: mounting the advance processing board on the keel according to the design drawings, and using aluminum accessories to connect the panel and keel. Hanging lightly the same level layer fiber cement boards on the keel, and then adjusting the horizontal and vertical degree of board through upper and lower steel wires. After that, checking the boards seam, whose width should be uniform according to the requirements of design. Last, tightening the stainless steel screws on the complete set of aluminum accessories.

(6) Board joint treatment: using the fiber cement board powder mixing glue to fill the seam, and then painting with special coating twice. When filling the gap, it is necessary to pay attention to the uniform and full filling.

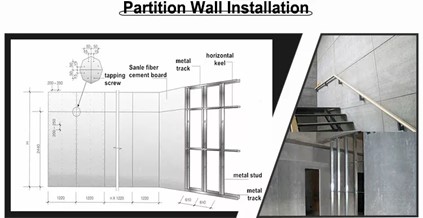

2. Partition wall installation

The top and bottom keels are fixed respectively top floor and on floor with expansion bolts. The vertical keel should be aligned well according to the requirement with laterally supporting keel installed. Cutting the board material to the dimensions needed (about 10mm lower than wall height). Board material is fixed on keel in anchoring seam way with tapping screw: the interval of tapping screw is generally about 200~250mm with screws sinking 0.5mm under the board face.

The expansion seam of about 4mm between boards should be kept. The shrouding should be fixed from the middle to the four sides and cannot be operated at multipoint simultaneously to avoid generating inner stress to make board material bucking. Before the fiber cement board is packed and fixed, glass wool or rock wool can be filled as required.

3. Floor board installation

Before laying the boards, the welding seam on the top surface must be polished flat and the welding spatter must be cleared away. Keep the longitudinal direction of the fiber cement board parallel to the main beam, any edge of the board must not be suspended, a gap of 3~5mm must be left between the board and the board, and the joint between the board and the board should be located in the center of the beam.

Selecting the countersunk head tapping screw, nailing on the vice-keel (Angle iron). Drill first and then nail, nail hole should be bigger than the diameter of the nail. Nailing starts from the center of the board, and then hits outwards, and finally hits the side nails. The nailing position of the side nail should be about 20mm from the edge of the board. The nail distance is 300~600mm. The joint can be injected with silicone sealant, or mortar can be used.

VI. Maintenance skills

After the fiber cement board is installed, it can be painted with various coatings, a waterproof coating is required for places exposed to the air. The joints of the fixed boards need to be filled with wood blocks or battens, and the entire surface of the board needs to be painted, which can prolong the service life of the board. Installation of fixed and painted fiber cement boards requires minimal maintenance. Thick and high-density sheets have good impact resistance, but thin and low-density sheets need protection from external impact.

The above is the detailed science about fiber cement board. If you have other ideas about WPC interior wall panel, please contact us. The professional WPC wall panel manufacturer, George Panel will make your dreams come true.

Quick Quotation