A Detailed Explanation of the Wall Panel Production Process

The term wall panel can be traced back to the time of Solomon, the son of King David of the Kingdom of Israel, in 970-930 BC. After Solomon succeeded to the throne of David, he built a temple for the supreme god. The main body of the temple was built of rock, and the interior was wrapped entirely with high-quality cedarwood, with no stone exposed, and called the wall panel .

The wall panel is not a modern product but has a profound cultural history and significance. The wall panel has suitable constant temperature and noise reduction, effectively protecting the building walls and having excellent decorative properties, covering the initially uneven stone walls on the back of the wall panel. And with the development of the times, wall panel design is more diversified. Therefore, wall panel has always been loved by people.

Nowadays, the building structure has been dramatically improved. In a market with many decorative materials, wall panels are no longer necessary for decoration. However, the wall panel can still attract the most successful people’s eyes because of its noble symbol and luxurious temperament. And with the rapid growth of the domestic economy, the people are satisfied with material pursuits and tend to pursue spiritual pursuits. In this way, the wall panel has once again entered people’s field of vision.

I. What is the wall panel?

Wall panel is a new wall decoration material that evolved from the ceiling. The same splicing and installation method dramatically simplifies the process and process of wall decoration. It is convenient and environmentally friendly from the rough embryo to the finished product.

II. Types of wall panels?

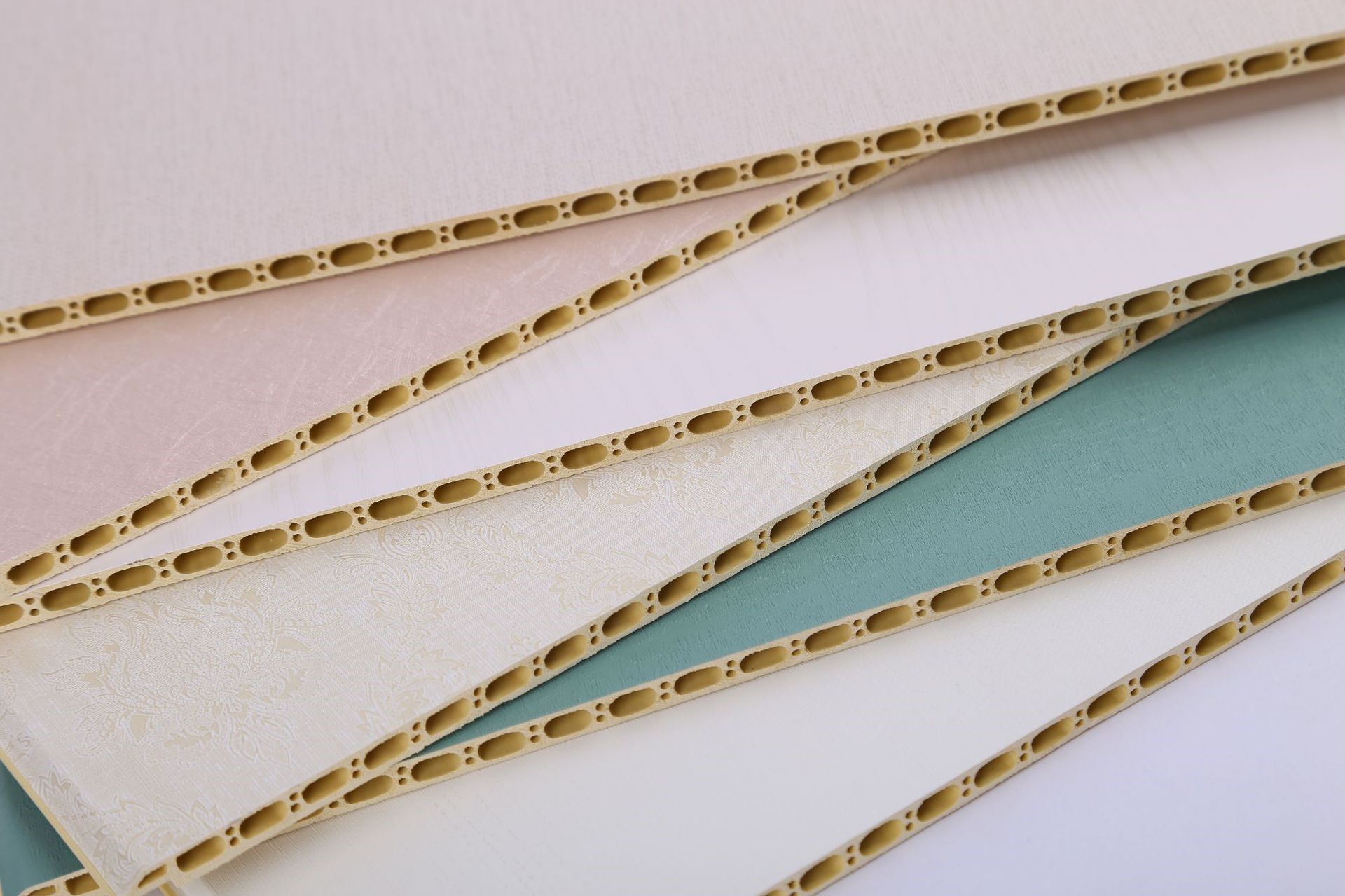

There are many types of wall panels on the market. The wall panel is mainly divided into WPC, PVC, SPC and solid wood in terms of materials.

1. WPC

The material is primarily light yellow, which has the characteristics of waterproof, flame retardant and insect-proof. At the same time, WPC panels for walls has muscular flexibility, is easy to cut and process, and has a moderate weight. It is the best choice among many materials. It can produce all the board types currently on the market. The surface technology of WPC panels for walls is mainly lamination, and some customized products will be added with spray painting and UV technology.

The material is primarily light yellow, which has the characteristics of waterproof, flame retardant and insect-proof. At the same time, WPC panels for walls has muscular flexibility, is easy to cut and process, and has a moderate weight. It is the best choice among many materials. It can produce all the board types currently on the market. The surface technology of WPC panels for walls is mainly lamination, and some customized products will be added with spray painting and UV technology.

2. PVC

PVC wall cladding price is the lowest among all materials and has the material properties of waterproof and mildew resistance. However, it cannot achieve the effect of fire and flame retardant. PVC wall cladding is highly lightweight and easily broken when squeezed and cut. The thickness of the material can identify it, and the substrate is generally white or beige. PVC wall cladding’s surface technology is mainly based on printing, and some customized products will add spray painting and UV technology. Only hollow, elongated, narrow products can be produced.

PVC wall cladding price is the lowest among all materials and has the material properties of waterproof and mildew resistance. However, it cannot achieve the effect of fire and flame retardant. PVC wall cladding is highly lightweight and easily broken when squeezed and cut. The thickness of the material can identify it, and the substrate is generally white or beige. PVC wall cladding’s surface technology is mainly based on printing, and some customized products will add spray painting and UV technology. Only hollow, elongated, narrow products can be produced.

3. SPC

SPC panel is made of stone powder mixed with PVC. SPC panel price is medium to high for all materials, and has the characteristics of waterproof, flame-retardant, insect-proof and mildew-proof. SPC panel is hefty and difficult to cut. The substrate is generally light grey or off-white. The surface technology is also mainly printing, and some laminations and some customized products will be added with spray painting and UV technology. Only hollow, long, narrow products can be produced or thin SPC panels.

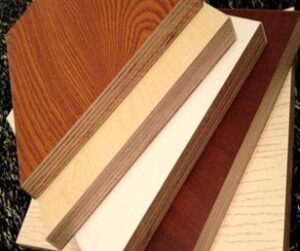

4. Solid wood

The solid wood wall panel is a more traditional decorative material, limited by processing machines, and its size is relatively fixed. The styles are less and backward, mainly wood grain. It is rarely used in the direct decoration of walls. Now it is mainly used for the decoration of furniture and cabinets.

Wall panels are loved and sought after by more and more people because of their green, environmentally friendly and easy-to-install features. The most significant volume on the market should be SPC panels, because the SPC panel is relatively cheap, but the main force of home improvement should still be WPC panels for walls, so that I will focus on WPC panels for walls.

III. The manufacturing process of the wall panel

1. Raw materials are essential

WPC wall panel uses natural bamboo powder, wood powder, calcium carbonate, polymer resin and other auxiliary materials for stirring. All of these ensure that the quality of the product is stable and green.

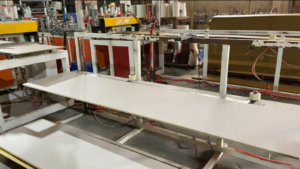

2. High-temperature extrusion process

This process is divided into three stages: feeding, melting and metering. Extrusion at a temperature of more than 200 degrees is used to avoid the generation of harmful gases such as formaldehyde.

3. Cooling technology

Wall panel extruded at high temperature must be cooled with water to ensure that the product will not peel and crack.

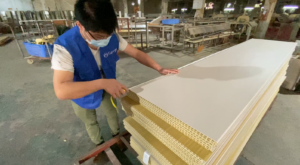

4. Plate lamination

After cutting and dust removal, the wall panel can be thermally coated according to the customer’s customized needs and special surface treatment. The wall panel has various colors and patterns and acts as a protective layer, making the product life longer.

5. Inspection shipment

After product inspection and packaging, the green, environmentally friendly and colorful wall panel can be delivered to the location designated by the customer. The process is simple, but it involves precise process technology. Only when the above links are strictly checked can everyone use them confidently.

IV. How do we identify the quality of WPC wall panels from the material?

1. Look

Looking at the color, thickness and structure, high-quality wall panels are generally beige, which is biased towards the color of bamboo and wood, and there are no black spots or particles at the incision. If the color is dark or there are spots, it may be made of recycled materials, or the formula is wrong, not environmentally friendly, and the service life is not long.

If the color is white, too much calcium powder is added, and the toughness of such wall panels is not enough. In addition, it depends on the thickness and structure. The thickness is generally 10mm, and the plate-shaped structure uses grooves combined with soundproof holes. At the same time, it has a co-extruded edge and presents a V-shaped groove when splicing. Such a wall panel is a standard and qualified structure.

2. Smell

Standard wall panels smell a touch of bamboo wood near the nose. Using fire to burn the board, no open flame, accompanied by a faint smell of bamboo and resin. Poor quality wall panels smell like a distinct plastic smell.

3. Ask

Ask the merchant or company whether they can issue patent certificates, production licenses, and product quality inspection certificates. Whether a national authority issues these documents. At the same time, ask the other party whether the after-sale warranty method, after-sale time and after-sale scope are indicated.

4. Check

Measure the weight of the wall panel by hand. If it is too light, it will be seriously foamed. If it is too heavy, too much calcium powder will be added. When purchasing, we can take a piece of the wall panel with a length of 3m and try to bend it. If it can form a circle at 360°, the toughness and quality are up to the standard, and the inferior wall panel will be too brittle and broken. In addition, see if the wall pane in the exhibition hall can be folded at a 90° angle during installation. The high-quality wall pane can be folded at a 90° angle, and the inferior wall pane can be folded at a 90° angle, which will cause cracks.

Precautions

1. Select the wall panel to see the three essential details.

The base material selection should be new; The surface layer of lamination is more than 14 filaments; the better the quality of lamination, the higher the fidelity of the wall panel; The choice of wall glue should be high temperature environmentally friendly lamination.

2. Select the brand to see the details.

When consumers choose wall panels, they often only pay attention to the mainboard part and ignore the internal materials misleading the merchants. This part of the auxiliary materials is equivalent to the building’s foundation, beams, and columns. It is easy to rust and deforms by cutting corners, causing the wall panel to sink or collapse. Therefore, consumers must observe when purchasing, and none can be sloppy.

3. Pay attention to practicality and quality.

Practicality is the most basic requirement of a product. If it is not practical, the decoration will lose its original meaning. The market price of wall panel products ranges from tens of yuan to several hundred yuan per square meter. The price is different, and the quality is also poor. There are many wall panel modules of low-priced unique products made of waste materials, which are light and thin and have a short practical life. Therefore, it is recommended that consumers not be greedy for small and cheap products when purchasing products and pay more attention to their quality.

4. Pay attention to health and environmental protection.

Bedroom decoration must pay attention to the quality of decoration materials, incredibly toxic substances such as formaldehyde have great harm to human health, and the release period of formaldehyde can even be as long as more than ten years. Therefore, everyone must pay attention to the environmental protection of the board when purchasing wall panels. My country’s standard for environmental protection boards is 10-30mg/100g, equivalent to the E2 standard.

5. Use the service with confidence.

When choosing wall panels, you should also pay attention to pre-sale, in-sale and after-sale services. With three materials and seven points of service, high-quality service can ensure the regular use of the product in the future. The front-line service personnel have received professional installation training. Consumers must observe the quality of these personnel when purchasing to enjoy high-quality after-sales service purchases.

Quick Quotation